NUS researchers develop wireless, ultra-thin and battery-free strain sensors that are 10 times more sensitive

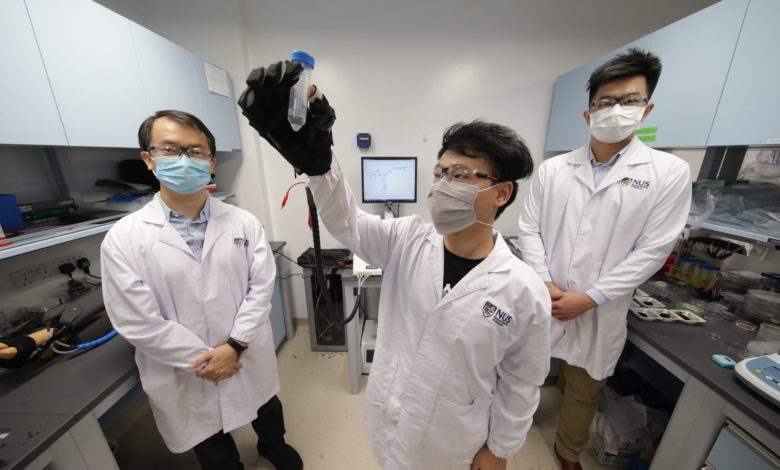

A research team from NUS, led by Assistant Professor Chen Po-Yen, has taken the first step towards improving the safety and precision of industrial robotic arms by developing a new range of nanomaterial strain sensors that are 10 times more sensitive when measuring minute movements, compared to existing technology.

Fabricated using flexible, stretchable, and electrically conductive nanomaterials called MXenes, these novel strain sensors developed by the NUS team are ultra-thin, battery-free and can transmit data wirelessly. With these desirable properties, the novel strain sensors can potentially be used for a wide range of applications.

Asst Prof Chen, who is from NUS Chemical and Biomolecular Engineering, explained, “Performance of conventional strain sensors has always been limited by the nature of sensing materials used, and users have limited options of customising the sensors for specific applications. In this work, we have developed a facile strategy to control the surface textures of MXenes, and this enabled us to control the sensing performance of strain sensors for various soft exoskeletons. The sensor design principles developed in this work will significantly enhance the performance of electronic skins and soft robots.”

Read full story at NUS news

Photo by NUS Singapore